Differences between SMT and traditional through-hole technology in PCB design

SMT is a fast, fully automated process that improves the accuracy of component placement, reduces manual labor, provides consistent quality and reduces cost. Let's introduce the advantages of through-hole to SMT conversion and the scope involved!

What are the advantages of through-hole to SMT conversion?

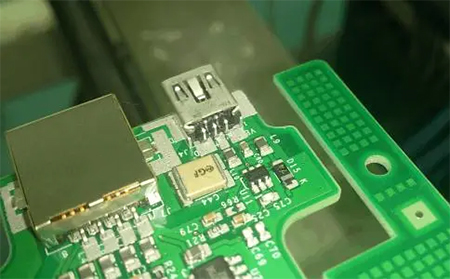

Surface mount components (commonly known as SMD - Surface mount devices) are smaller and lighter than through-hole components. This allows for lighter panels and higher density components.

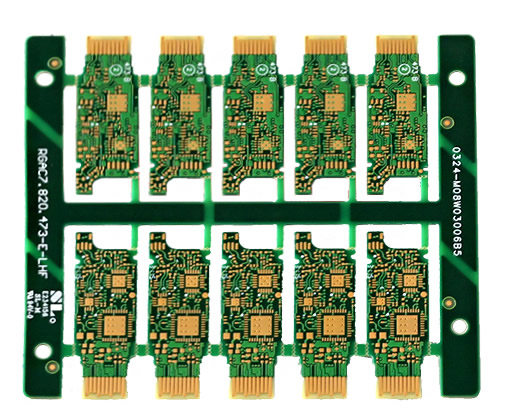

SMT does not require pre-drilled plates, which reduces manufacturing time and cost. The process is also fully automated, allowing rapid production of highly accurate and repeatable circuit boards, further reducing costs.

Components can be mounted on both sides of the board because the component leads cannot pass through the board. This opens up more design possibilities, and more functions can be packaged into the same board area.

Manufacturers stopped using many through-hole assemblies and most advanced assemblies were not compatible with through-hole installations. SMDS are also usually less expensive than similar products with through-holes.

Automatic assembly improves installation reliability and reduces errors. It also allows for more thorough and accurate testing of the circuit board.

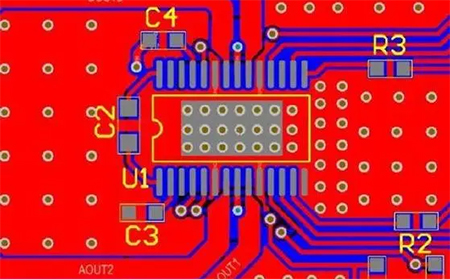

What are the through-holes involved in SMT conversion?

When evaluating the product for conversion, we identify all potential issues that may affect the board, such as:

1. End-use of products (especially temperature and temperature cycling)

2. Mechanical constraints (shape factor, vibration, etc.)

3. Component voltage, current and rated power

4. Component availability

5. Programming and testability issues