What should be noticed in PCB multilayer production process?

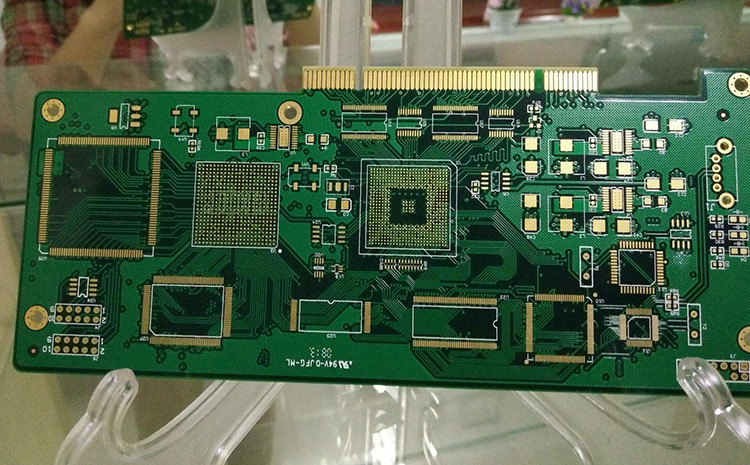

PCB multilayer board usually refers to the circuit board of more than 10 layers, it has an insurmountable gap with the traditional multilayer board, for enterprises or for product quality, have put forward very high requirements. At the same time, its application field is very wide, and there is a deep development potential waiting for us to explore. Today, we will study what we need to pay attention to in the production process of multilayer board!

1. The pressure

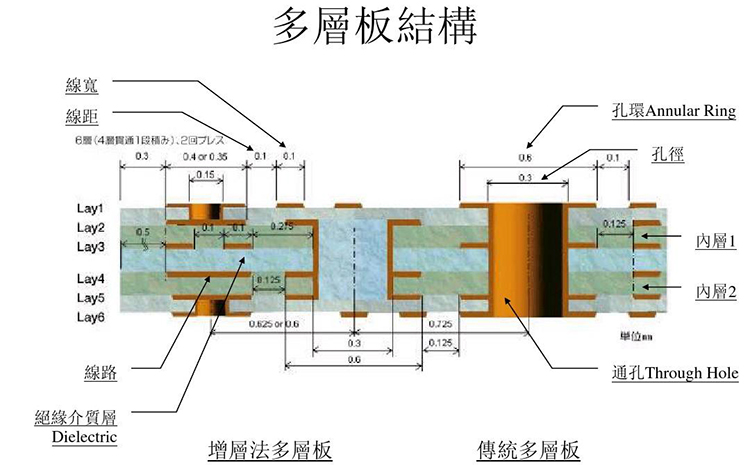

Multilayer panels must have an rigrous process. In this process, if you are not careful, there will be stratification, skateboarding and other phenomena. Therefore, the performance of the material must be considered in the design. The more layers there are, the more difficult it becomes to control expansion and contraction and compensate for dimensional coefficients, which brings problems. If the insulation is too thin, test failures may occur. Therefore, the more attention is paid to the stamping process, there will be more problems at this stage.

2. Inner line

The materials used to make multilayer panels are also very different from other panels. For example, the copper skin on the surface of the multilayer board is thicker. This makes the inside layout more difficult. If the inner core plate is very thin, it is prone to abnormal exposure, which may be due to folding. Generally speaking, the unit size of multilayer board is relatively large, and the production cost is very high. Once the problem occurs, it will bring huge loss to the enterprise. The income may not make ends meet.

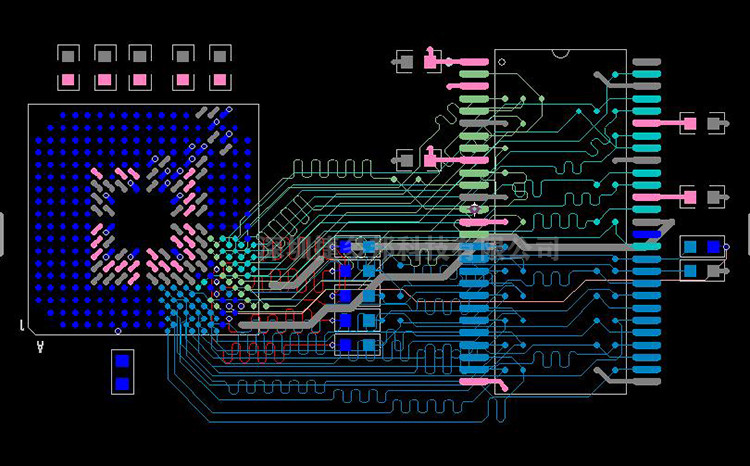

3. The alignment

The more layers there are, the higher the level alignment requirement becomes. Generally, the interlayer alignment tolerance is controlled to ±75μm. Due to the influence of size, temperature and other factors, multi-layer alignment control of the difficulty coefficient will be very large.

4. The drilling

The difficulty of drilling is also increased because the multilayer panels are made of special materials. It is also a test of drilling technology. Due to the increase in thickness, the drill pipe is prone to fracture, which can lead to a range of problems such as skew drilling. We should pay more attention!